In January 2018, in collaboration with the University of Innsbruck and Luxner Enigeneering ZT GmbH, we launched a joint K-Regio project entitled “Optimised ceramics/New applications of sintered materials through model-based optimisation of competing technical requirements: Strength – Thermal Conductivity – Mass Transfer”. After three years of intensive research, we are very pleased to present the first results.

What’s it about?

Within the K-Regio project, model-based methods for the specification of novel ceramics were explored. The aim was to develop a multiscale model that takes into account pore space as well as pore space properties and quantifies the resulting physical properties. The project ran until December 31, 2021 and was co-funded by the European Regional Development Fund (for more information on IWB/EFRE, see www.efre.gv.at).

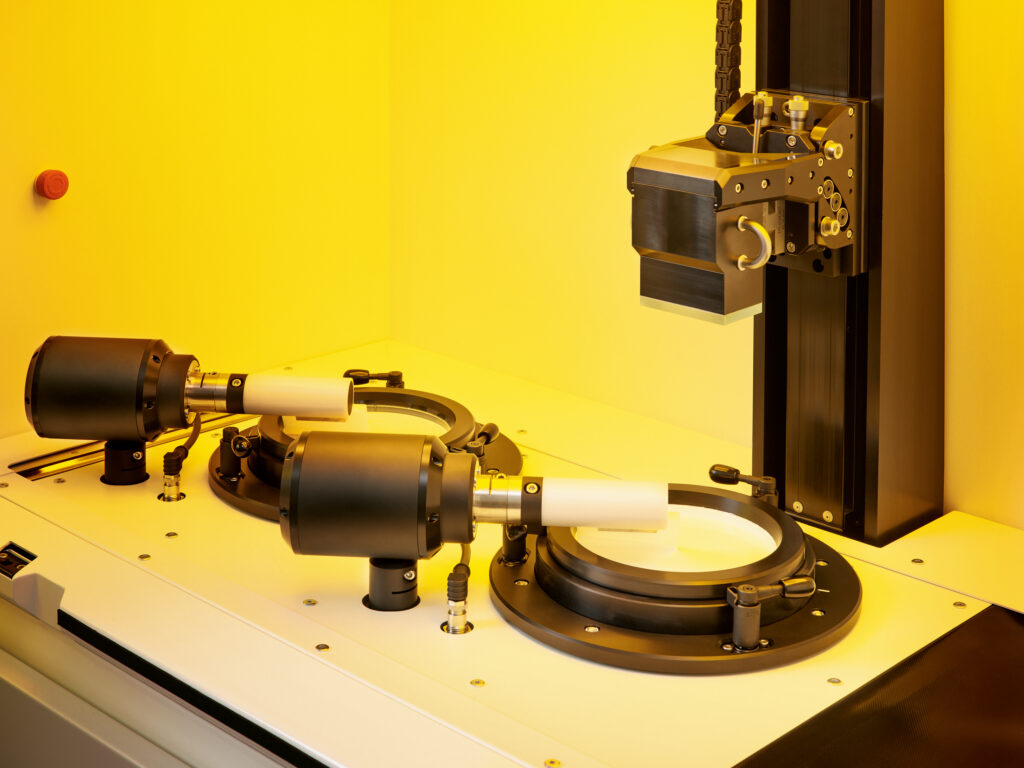

Together with the Department of Materials Technology headed by Univ.-Prof. Dipl.-Ing. Dr.techn. Roman Lackner and the team of Luxner Engineering ZT GmbH – which specializes in linear and nonlinear structural analyses – we investigated the pore space properties of numerous steatite ceramic samples using 3D X-ray microscopy in combination with image-based pore space analysis.

From this intensive collaboration, we are taking away two key results for future products and product properties:

- We were able to achieve an improvement in ceramic sealing discs for metering the flow rate in drinking water applications.

- We have developed new products such as porous ceramics for filtration and ceramic support structures for chemical applications.

The University of Innsbruck publishes the results from the joint research in detail, we would like to provide insights here in the blog and will gradually present the publications of the project team.

We start our series with an overview of the procedure for pore space determination in steatite from the official manuscript:

A large number (>150) of porous steatite ceramic rods were prepared using different types of renewable plant fiber products as pore-forming agent with mass contents ranging from 2 to 10%. In addition, dense steatite ceramics were synthesized for comparison within a gas furnace at sintering temperatures between 1300 and 1350 °C.

High-resolution 3D X-ray microscopy facilitated a non-destructive, direct investigation of the three-dimensional pore space and microstructure. By using image-based pore space analysis, various pore space parameters, such as, e.g., pore volume, pore-size distribution, and pore connectivity were determined. In addition to the characterization of the pore space, phase analysis, structural and chemical investigations were carried out by X-ray powder diffraction, electron microscopy, Fourier-transform infrared,

Raman and X-ray spectroscopy.

Finally, to evaluate the influence of characteristics on the physical properties, elastic, strength and thermal properties were determined. With the increase of porosity, the flexural strength and thermal conductivity values decrease from σf = 123 ± 8 to 37 ± 5 MPa and λ = 3.22 ± 0.02 to 1.77 ± 0.02 W/(m ∙ K), respectively. The obtained experimental results were discussed by means of micromechanical models, highlighting the effect of pore-space morphologies on the physical performance of porous steatite ceramics.

We would like to take this opportunity to thank the project partners for their great cooperation and the European Regional Development Fund for its co-financing.

If you don’t want to miss the further contributions around the research results, we recommend you to subscribe to the Steka newsletter. Click here to subscribe.